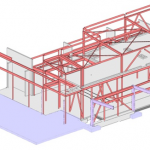

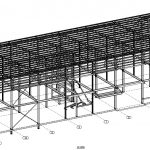

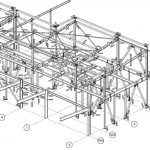

Once a project is secured the detailing process begins. We have two in-house detailers using Tekla Steel Detailing software whose role is to take the design drawings and create component drawings that can be interpreted by the workshop staff.

Our detailers are proactively involved in the design process to achieve the most efficient and accurate end result for the customer. Working closely with the project engineers and architects and the rest of the project team, they provide in-house fabrication and erection drawings for each project. This detailing information is transferred into their new robotic plasma cutting and coping machine to efficiently streamline the process from detailing to the fabrication of structural steel.

Our detailers are required to carefully detail on all kinds of architectural designs – some more technically challenging and demanding than others. The outcome of these designs can be striking and very satisfying to see when fully assembled and installed, such as the Memorial Park Rocket Slide.

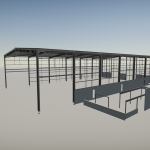

From design concept…

…to finished project.