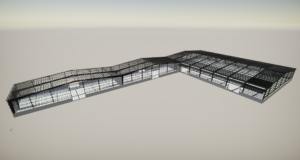

Welcome to our project showcase - Hinuera Sheds: Recycling Steltech Structural Steel Beams for Hinuera Storage Sheds 2023!

Key Project Statistics:

- Material Used: 380 tons of structural steel, including nearly 200 tons of recycled Steltech beams.

- Purlins: 11.5 km in total

Project Overview:

Client Background: Working closely with Sabre Construction, the client acquired Steltech beams from a demolished building at the port and aimed to repurpose them for constructing storage sheds in Hinuera. Facing time constraints, the Steltech material was transported over the Kaimai Ranges to Hinuera where the engineering team had to finalise a design using what was on site.

Project Phases:

- Material Acquisition and Transportation:

- Procured Steltech beams from a demolished port building transported from Hinuera to Steelworks for fabrication and painting then back to Hinuera every few days during the course of the project.

- Due to time constraints the cyclic flow of transporting material from Hinuera to Steelworks then back to Hinuera was key to delivering the project successfully.

- On-Site Design and Modification:

- Engineers finalised the shed design based on available Steltech beams on site at Hinuera.

- Steelworks detailer Mike Aldridge worked with the Engineers and client to create construction drawings for fabrication and installation.

- Fabrication:

- Adjustments involved shortening and modifying Steltech beams to fit the new design requirements.

- Fabrication included weld testing old welds, removing & gauging out old non-compliant welds and rewelding into place; and removing old connections.

- New steel components were fabricated to enhance structural integrity.

- Painting and Finishing:

- Fabricated steel components underwent a blasting and painting process for durability then transported back to Hinuera for installation.

- Final Installation:

- Our site team led by Nic Taituma are assembling the 380ton structure over a 3 month period to build the sheds utilizing the recycled Steltech material.

- Working strategically bay by bay to install and erect 5ton Steltech beams and 11.5km of purlins.

Challenges Overcome:

- Time constraints during the initial phase prompted on-site design finalisation.

- Weld testing, removal, and replacement of non-compliant welds for structural integrity.

- Transportation of steltech beams from Hinuera to Steelworks over the Kaimais in sequence.

- Size of steltech beams and safely fabricating in the workshop, loading and transporting and installing on them on site.

Sustainability Impact:

- By recycling Steltech beams, the project contributes to environmental sustainability.

- Repurposing Steltech steel reduced the demand for new raw materials.

- Endorses the longevity and lifecycle of steel as a product of choice in construction.

Project Outcome:

- Successful construction of storage sheds in Hinuera using recycled Steltech material.

- Demonstrates the viability and environmental benefits of repurposing structural steel.

Conclusion: This project exemplifies our commitment to innovative and sustainable construction practices. The journey from salvaging Steltech beams to their transformation into functional storage sheds showcases our expertise in working with clients wanting to recycle material for structural engineering. We are proud to have contributed to both environmental sustainability and the efficient use of existing resources.

Steelworks NZ Ltd is committed to a sustainable vision where we provide steel products as a critical enabler in New Zealand’s journey to a low emission economy. Part of this journey includes achieving our circular economy programme, which involves reusing or recycling steel for your upcoming project with us.

Working closely with Sabre Construction and the client, SH29 Limited, reusing and repurposing Steltech is a major component of the structural integrity of Hinuera Sheds...and the result is AWESOME! Economical, efficient, aesthetic and playing a huge part in reducing its carbon footprint, this building is a showcase for how effective the use of steel is in sustainability of the construction industry.

Click here to see video footage of the building in construction: